OVERVIEW

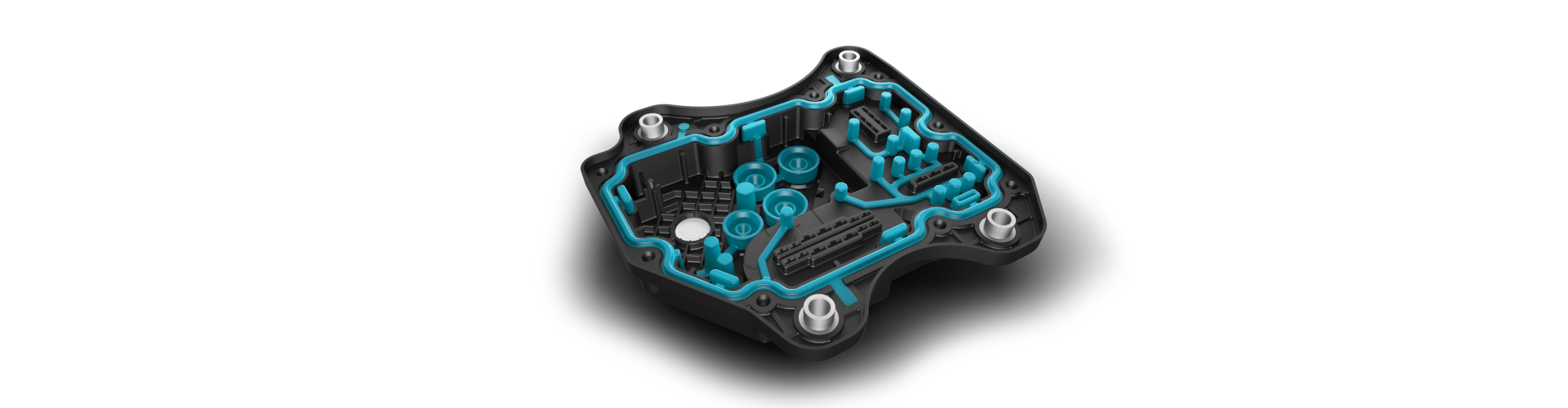

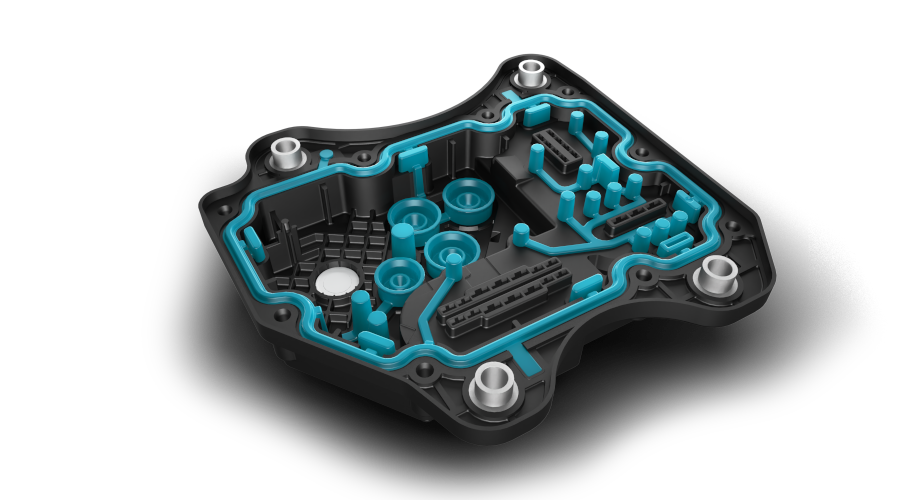

Precision and Innovation in Multimaterial Components: At Datwyler, we specialize in crafting 2K, or overmolded parts, combining Liquid Silicone Rubber (LSR) and thermoplastics to deliver custom component solutions for various industries, including sanitary, HVAC, off-highway, and automotive applications. Our approach integrates our deep materials expertise, operational excellence, and innovative solution design to co-create the right solutions for you, efficiently and effectively.

MATERIALS

• LSR: Leveraging our extensive expertise, we use LSR to produce lightweight, rigid parts that enhance assembly accuracy and efficiency in automated systems, reducing potential errors.

• Thermoplastics: We offer a wide range of thermoplastic solutions, ensuring flexibility and adaptability for your specific needs

EXCELLENCE

• Vendor Relationships: We maintain strong partnerships with suppliers to access a full range of LSR grades.

• Precision Manufacturing: Our advanced machinery allows us to control finer details and maintain tighter tolerances.

• High-Quality Processes: We implement high-yield processes and precise temperature control to insure the best results.

• Mold Maintenance: We understand the importance of controlled mold maintenance to minimize flashing.

• State-of-the-Art Technology: Our latest 2K part manufacturing machinery guarantees top-notch quality solutions.

THE DATWYLER ADVANTAGE

- Swiss Quality, US Know-How: Combining Swiss precision with American innovation.

- One-Stop Solution: From tool-making to part quality checking, we manage the entire process, providing you with a single point of contact and full control over the quality assurance process.

For reliable, efficient, and high-quality LSR components, trust Datwyler to deliver solutions that meet your unique requirements.