OVERVIEW

Quick turnaround on custom machined metal parts

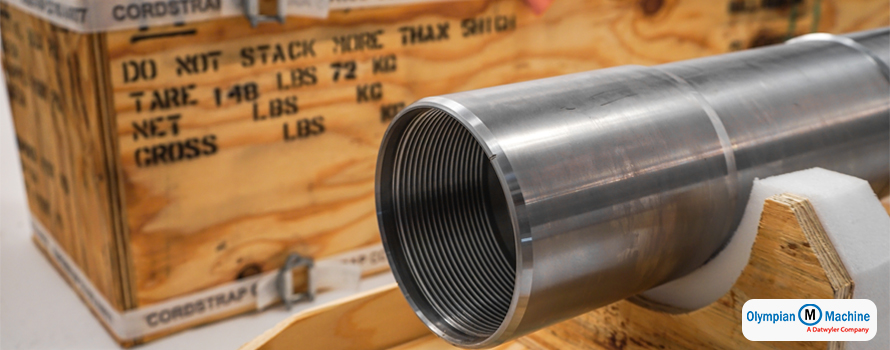

At Datwyler’s Olympian Machine, we are committed to delivering exceptional quality and swift turnaround times for custom machined metal parts. Our facility is equipped with a range of advanced lathes and mills, ensuring efficient processing of both small and large custom orders. Explore our comprehensive list of equipment and capabilities to see how we can meet your specific machining needs.

INDUSTRY

Durable Solutions for the Oil & Gas Industry

Understanding the rigorous demands of the Oil & Gas industry, we know that metal components are often subjected to some of the harshest operational environments. To counter these challenges, Olympian Machine offers a variety of specialized coatings, plating, and other treatments designed to enhance corrosion resistance, combat chemical attacks, and reduce wear and tear. Our goal is to extend the lifespan and reliability of your components, ensuring optimal performance under demanding conditions.

MATERIALS

Materials include:

| Alloy steel (4130-4145, 4340, 8620, 9310) |

Nickel (400, K500, 625,718, 945, 925) |

| Aluminum (1100, 2024, 3003, 5052, 6061, 6063, 7075) |

Stainless steel (303, 304, 316, 410, 420, 17-4PH, 13-8PH, 15-5PH, NIT50, NIT60) |

| Beryllium Copper (C17200, A25, AT (TFOO), HT (TH04), C173) |

Other (Aluminum Bronze, Hyper Chrome, Inconel) |

| CF Carbon (1018-1026, 12L14, 1215, A105, A350-LF2) |

If you don’t see your material listed above, contact us.

We work with a variety of specialty materials.

THE DATWYLER ADVANTAGE

Whether you need a custom solution or want to learn more about our protective services, our team at Olympian Machine is here to assist. Contact us today for detailed information or to request a quotation tailored to your project’s specific requirements. Trust in our expertise and technology to provide the machined metal parts that drive the success of your operations.

Looking for more Machined Metal?

Know what you need?

Contact one of our advisors today