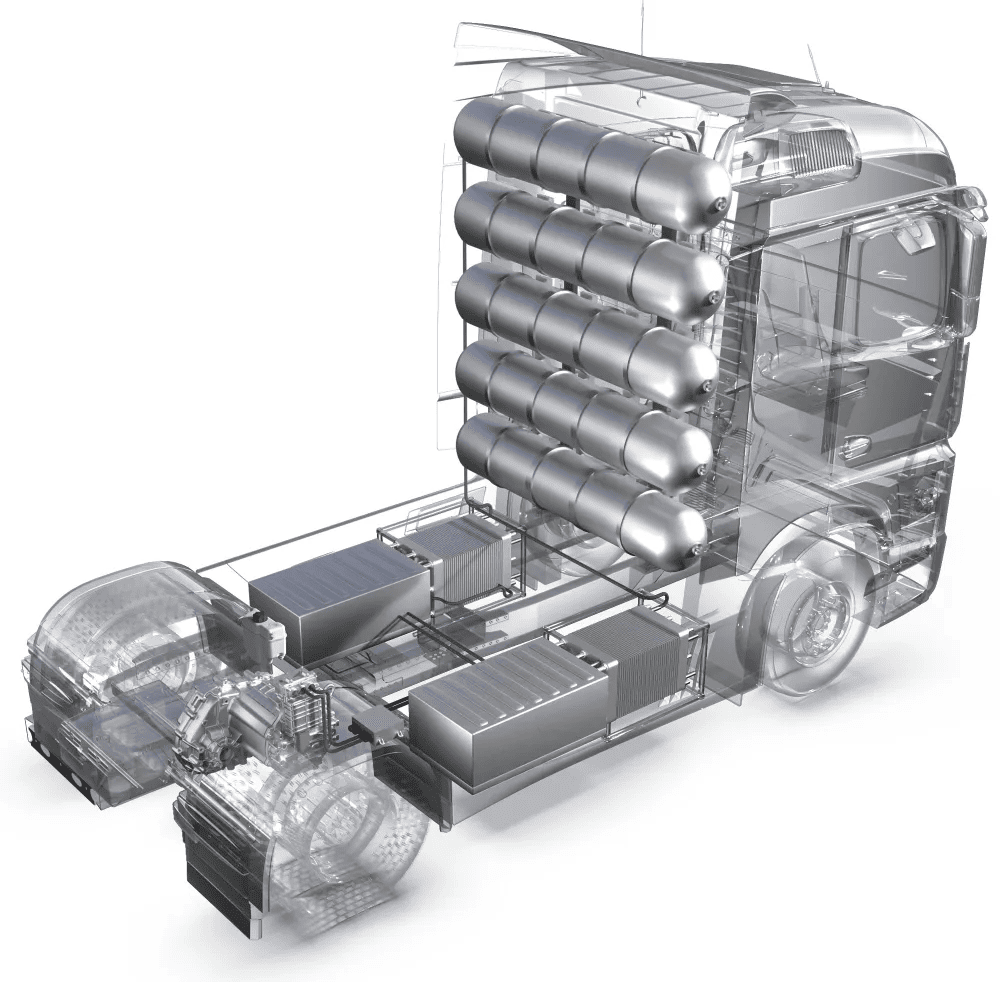

At the 31st Aachen Colloquium for Sustainable Mobility, which was held from 10-12 October 2022, Datwyler, FEV Europe GmbH and the Fraunhofer UMSICHT presented a detailed paper on the development of the BiFoilStack – a Novel cell and stack design with compound-foil-based bipolar plates for heavy-duty fuel cell systems. Heavy-duty commercial vehicles require fuel cells with a service life in excess of 30,000 hours, which historically has been challenging for many components – particularly metallic bipolar plates, which can corrode in the humid and acidic environment of the cell.

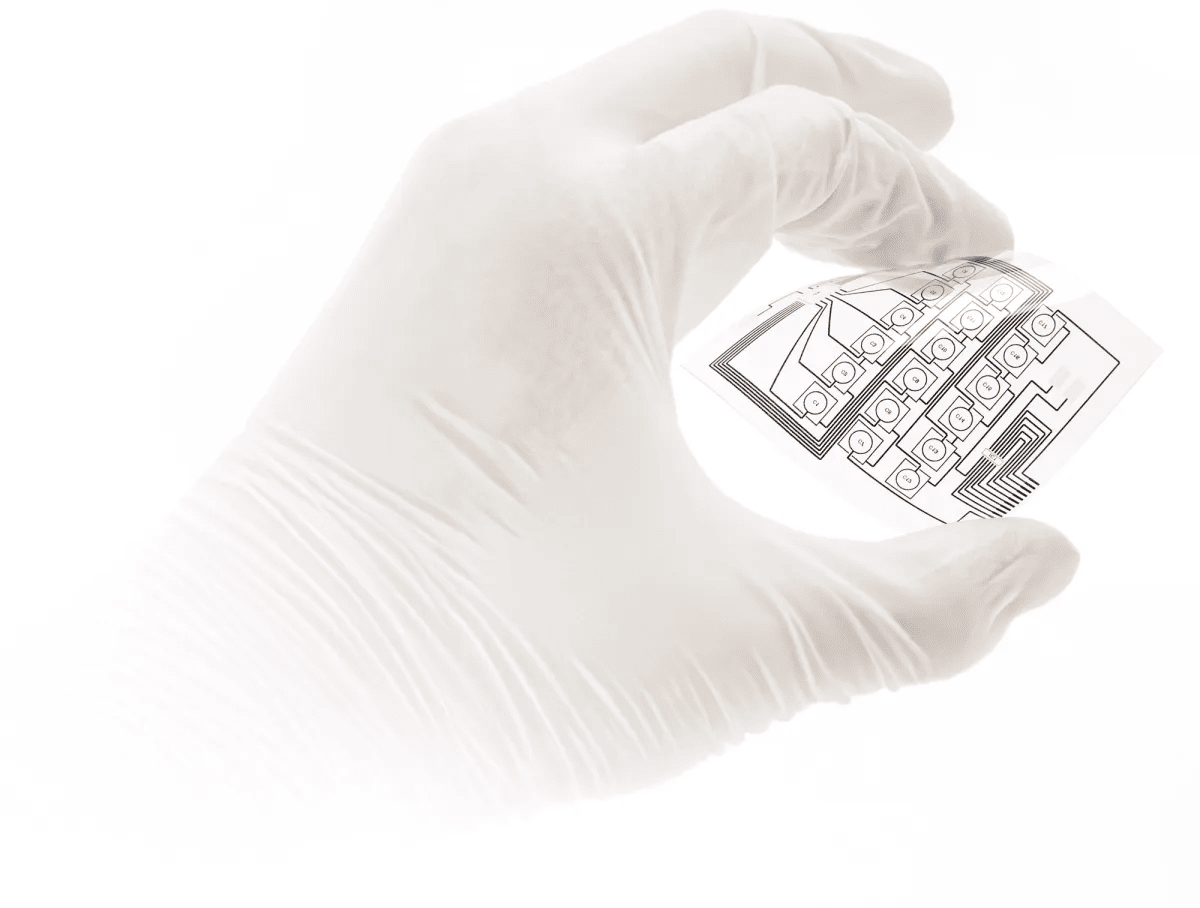

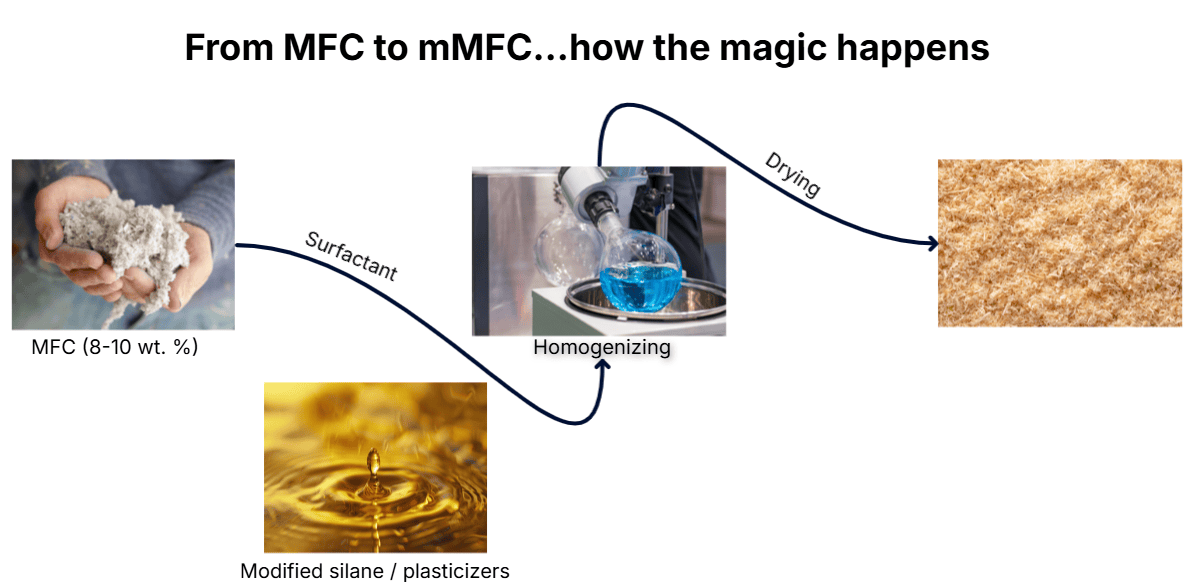

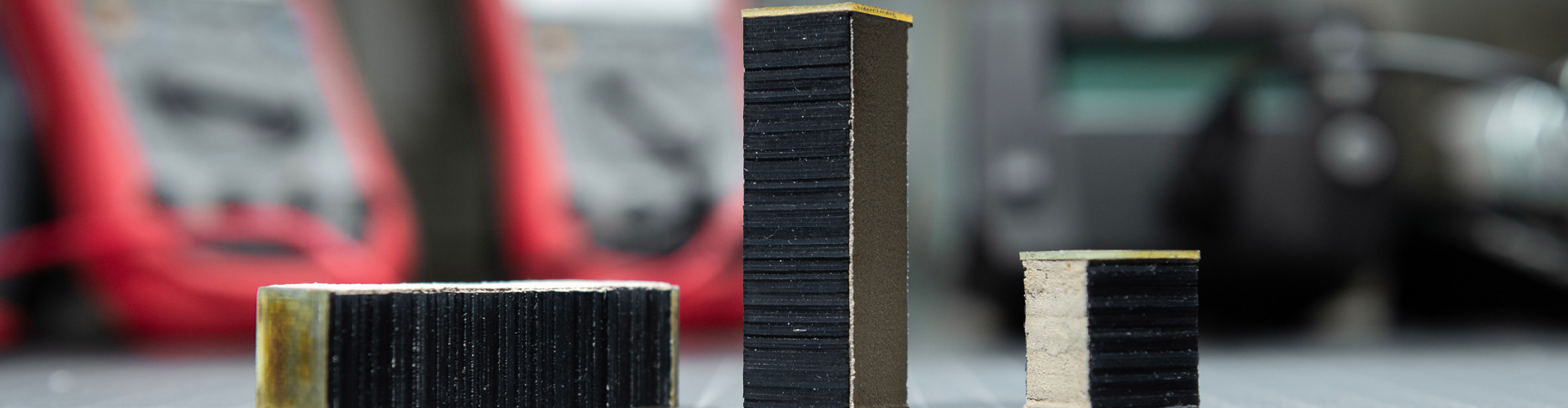

BiFoilStack is a public funded project with the aim to further enhance a novel base material to produce bipolar plates. Manufacturing processes have been elaborated, and dedicated cell and stack designs derived to exploit the additional design freedoms the material offers. The novel solution combines the advantageous features of metallic and graphitic plates – substrate thickness close to metal, superior corrosion resistance, and cost-effective production processes.

“We are incredibly proud to have been given the opportunity to present the project and status of our developments at Aachen with our partners. Hydrogen and fuel cells have been widely recognized as a cornerstone for the electrification of the heavy-duty sector. To date, their industrialization has presented significant challenges, however this project will go a long way towards accelerating their development.”

Dr. Samira Jafari

Global Head of Engineering Mobility

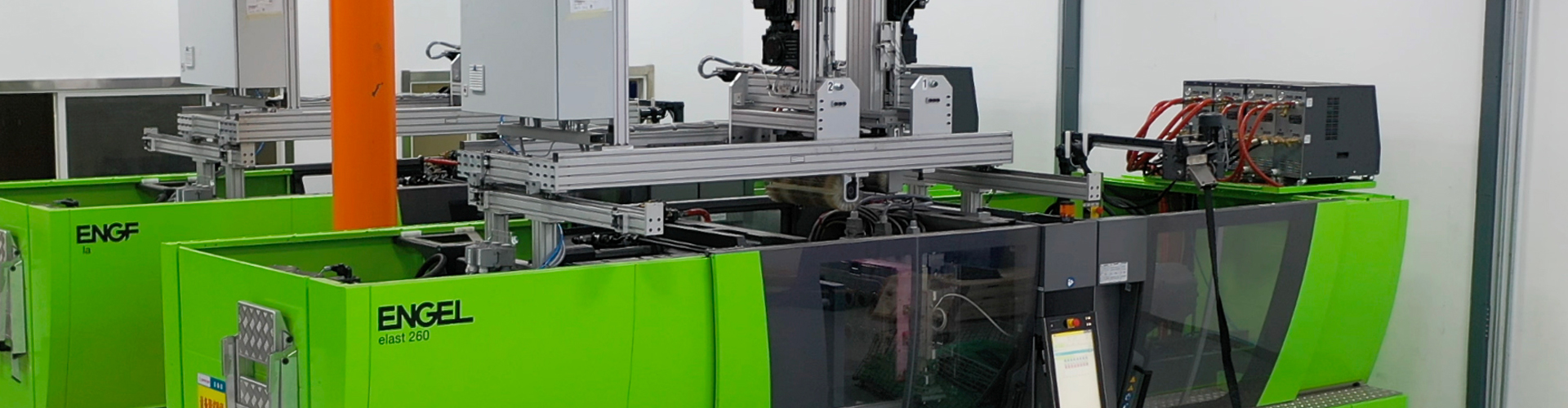

The consortium consists of various industry players and research institutes, and Datwyler will continue to expand on its important work in the area of hydrogen and fuel cells by delivering advanced processes for the manufacturing, forming, welding and sealing of the novel bipolar plates. A multi-disciplinary team of engineers and material scientists from different entities are participating in this project, which commenced in December 2021 and will run until December 2024.