Advanced, compact sensor technologies are in greater demand as digital transformation accelerates and connectivity needs rise. A highly established application-critical elastomer manufacturer, Datwyler has positioned itself at the forefront of these developments, studying the associated challenges and requirements to offer a range of innovative solutions.

Among these solutions, printed electronics show particular promise due to their strong synergy with elastomers – a material class that we have mastered over decades. By leveraging our extensive expertise in elastomer development and production, we aim to not only accelerate the adoption and deployment of printed electronics but also make significant contributions in support of digital transition and enabling a wide range of groundbreaking applications.

Next-Generation sensing:

thin, customizable and efficient printed electronics

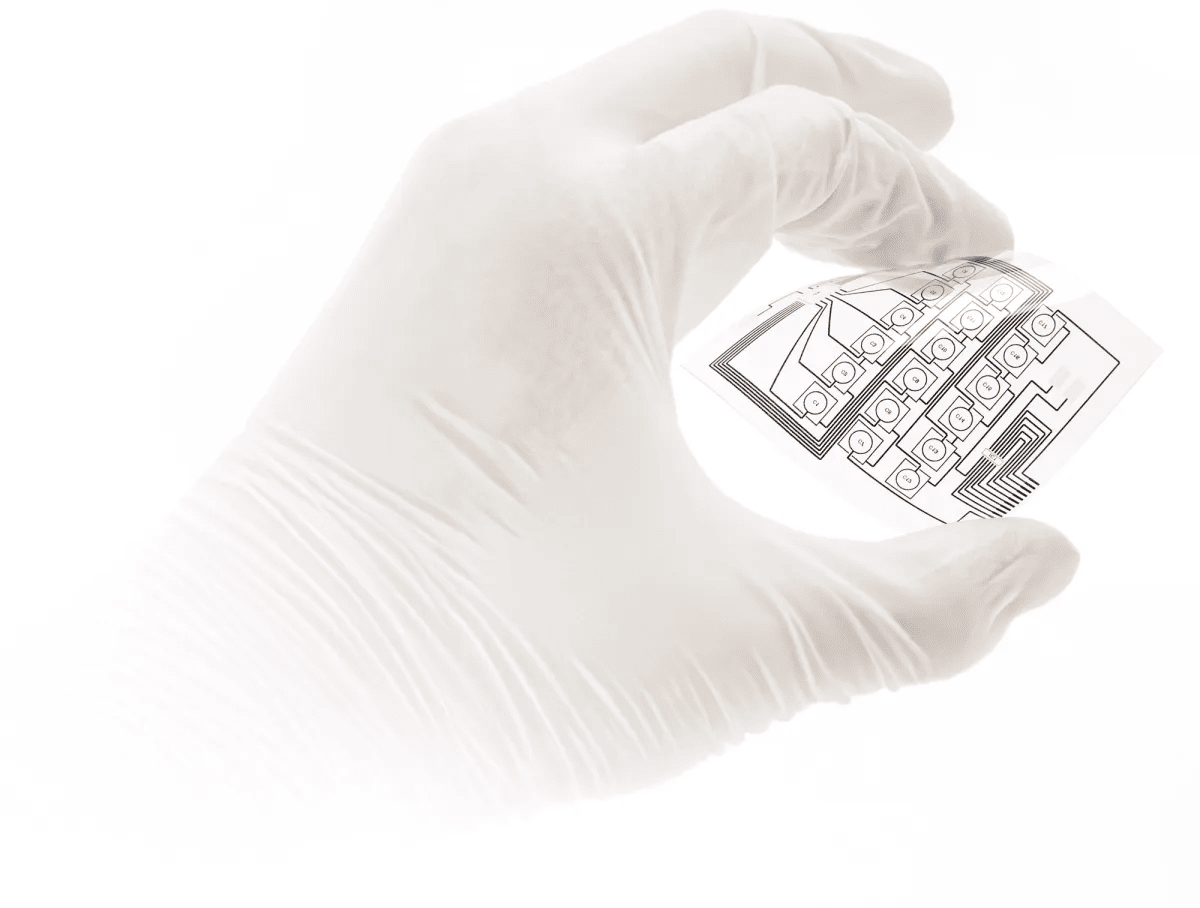

As enhanced product intelligence becomes more and more prevalent, adoption and interest in relevant and integrated sensing technologies amplifies. Printed electronics capable of measuring parameters such as pressure, temperature, humidity, and even biological markers are well-positioned to meet this growing need.

Often as thin as a few tens of micrometers, these devices offer significant advantages such as lightweight construction, cost-effectiveness, and geometric customization. Furthermore, the potential for large-scale manufacturing enhances their appeal. By facilitating widespread deployment of conformal and even stretchable sensing, printed electronics are broadening the scope and depth of digitalization possibilities.

However, like any other technology, printed electronics are not without any challenges. One is long-term resilience – how well these components can withstand the rigors of use over time. Another is environmental sensitivity, as performance can be impacted by conditions such as temperature, humidity, or exposure to various gases and substances. As a result, the complexity of integrating these electronics into different applications and systems – a burden previously relegated to final integrators – can pose difficulties.

Synergy of elastomers and printed electronics:

enhancing durability and performance

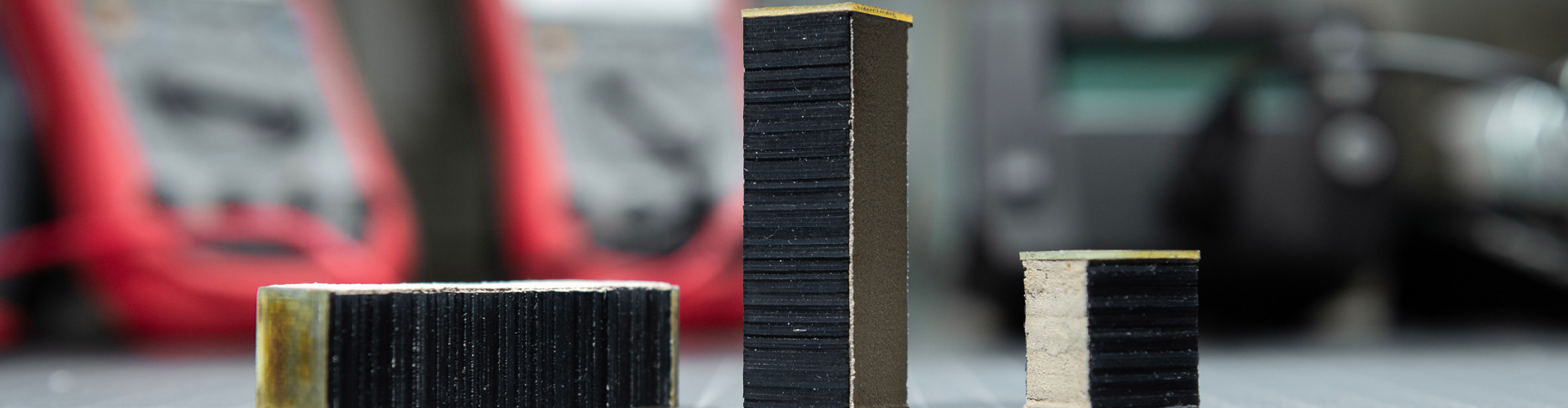

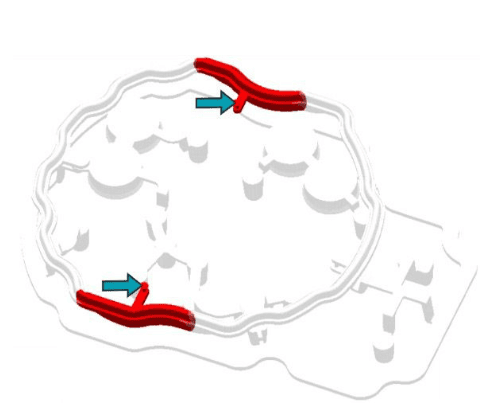

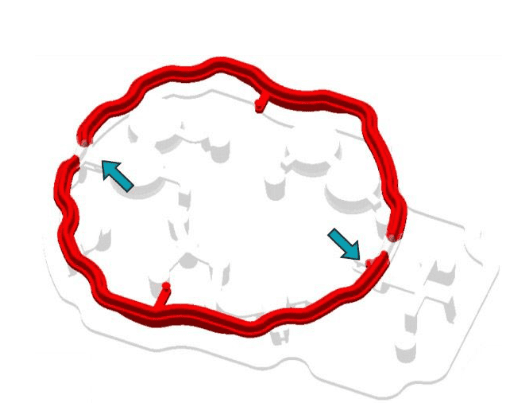

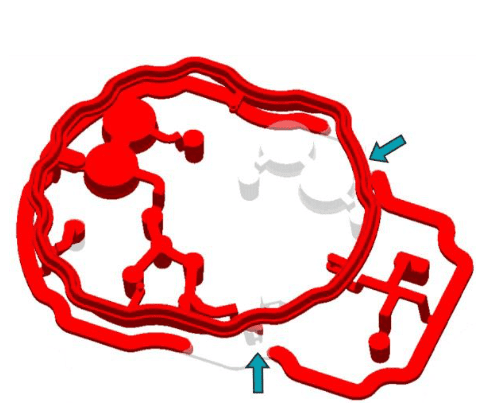

With their high durability and flexibility, elastomers are an excellent combination material class for printed electronics.rnrnThis approach significantly enhances the lifespan of printed electronics and preserves their performance.rnrnJust like printed electronics, elastomers allow for a large amount of customization, and our development, formulation, and production expertise allow us to tailor their properties to meet application-specific requirements. The material can be optimized to resist environmental conditions, conform to tight mechanical constraints, and even acquire unique attributes such as electrical or thermal conductivity.rnrnTo illustrate this synergy, we need to consider force-sensitive resistors (FSRs). Typically, FSRs can be vulnerable to external influences and mechanical stress. However, when these are embedded in customized elastomers, they acquire a robust, soft interface with the outside world. This additional layer not only provides protection but can also help shape the force-transfer function from the point of contact to the point of measurement (FSR surface), both of which can be tuned. This highlights the value of combining printed electronics with customized flexible and resilient material.

Reinventing production processes:

reliability in embedding printed electronics

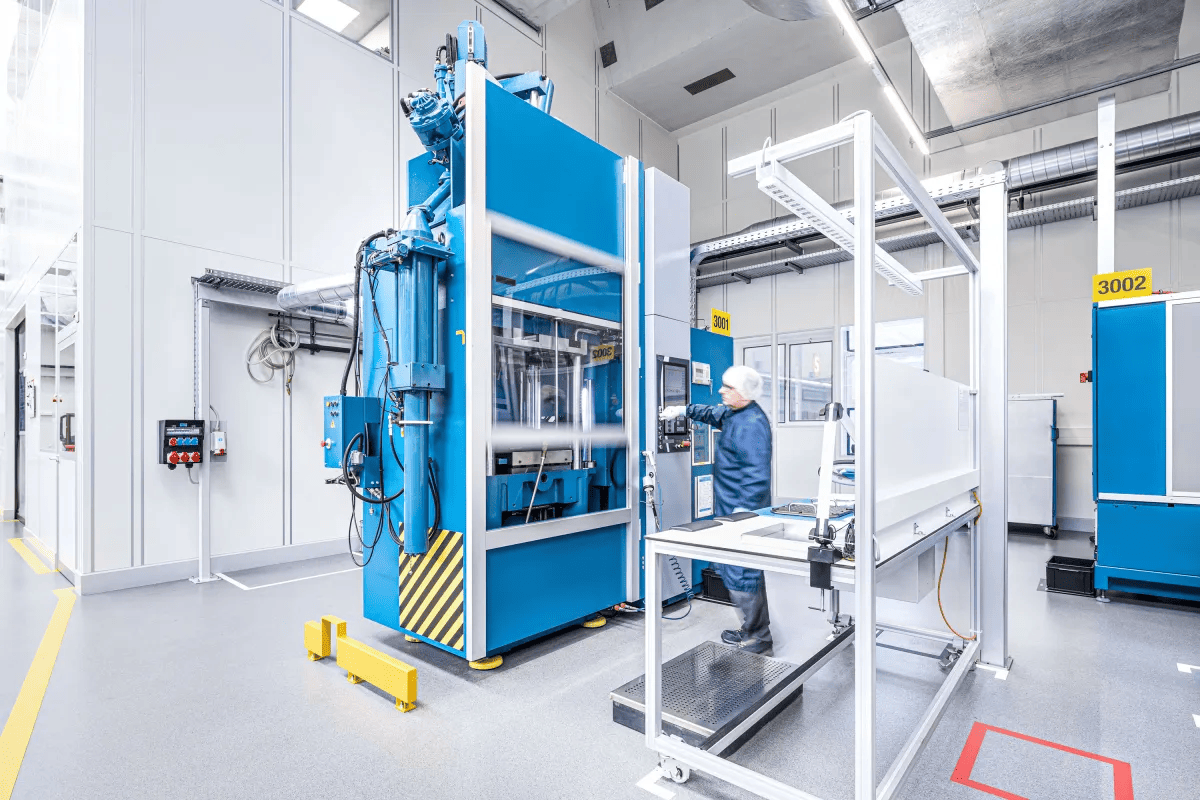

Meeting the demands for complex geometries and unique applications requires an evolution in production processes. Techniques such as calendaring, compression molding, and injection molding have been revamped to ensure the accuracy of critical elements in sensor embedding such as positioning, alignment, but also survival. From simulation to actual production, Datwyler has developed and refined a broad range of processes to achieve repeatable and reliable embedding of printed electronics within elastomeric material.

Simulation and optimization:

tools for precision and performance

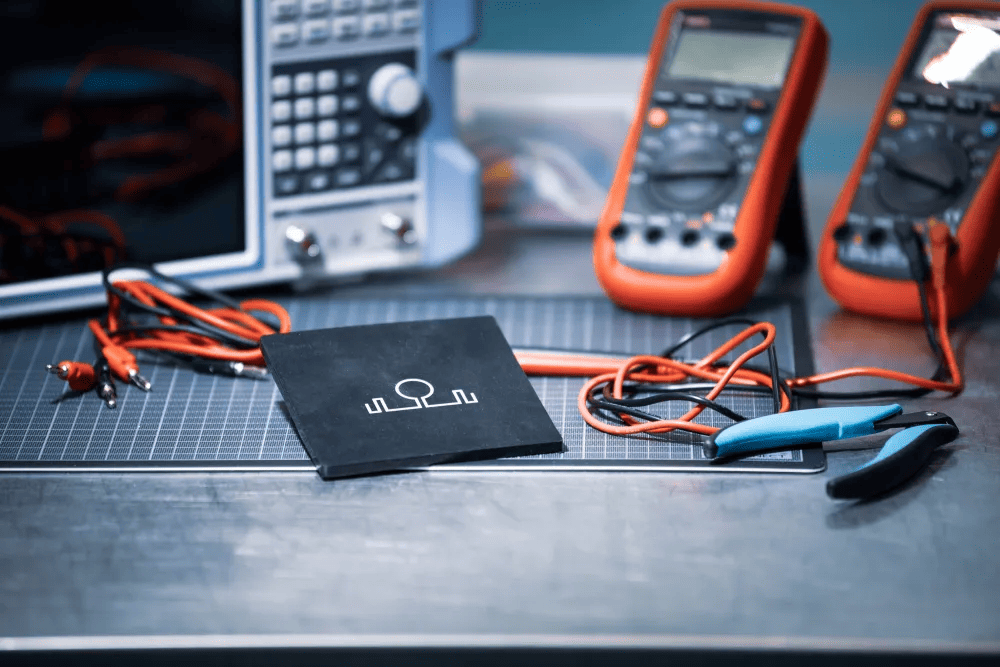

Simulation plays a pivotal role in Datwyler’s development process. It enables modelling of the elastomer’s mechanical behavior and evaluation of the embedding procedure’s impact, which, in turn, allows to anticipate the system’s performance contour. This proactive approach significantly trims down development lead times and enables swift iteration cycles.

Beyond the scope of classic FEM simulations, Datwyler’s capabilities extend to process simulation such as injection molding. These predictive tools support our efforts to maintain high performance standards and secure long-term repeatability of the production process.

The focus on sensor-compatible methods further facilitates control over the performance of these embedded systems, allowing for refined application-oriented optimization.

Beyond simulation and production, Datwyler also puts a high emphasis on rigorous testing of the resulting systems under realistic conditions. We collect extensive experimental data from the embedded sensors and compare this with our initial simulation results providing us with invaluable insights into the real-world performance and potential discrepancies. By feeding these findings back into our models, we enable iterative improvement and continually enact necessary adjustments.

Delivering consistently at scale:

high-volume production capabilities for exponentially growing needs

The rising demand for embedded electronics solutions requires not just customization, but also scalability. With our high-volume production capabilities, stringent quality controls, and robust processes, Datwyler is well-positioned to deliver consistency on a large scale. Every day, Datwyler produces more than 100 million defect-free components.

Unlocking new applications

“The integration of printed electronics and elastomers is paving the way for novel applications. In the future, we see a larger role for printed electronics across sectors including mobility, healthcare and general industry. By embedding these sensors in tailored elastomers, we can deliver resilient, high-performance products that meet the unique requirements of different sectors.“

Yassine Ahaggach

Advanced Technology Development Manager

Yassine Ahaggach