passion for unmatched quality, our approach to manufacturing and production – DPS, the Datwyler Production

System – brings in US know-how and is evident in every aspect of our work, across all our global sites.

From our advanced tooling facilities in Switzerland, to our extensive US manufacturing and development sites in California, Louisiana, Ohio and Texas, each location stands as a testament to this commitment, boasting capabilities that embody our dedication to precision and quality – and our ability to leverage expertise and capabilities from across our sites. That makes any site you engage with a one-stop shop for meeting your sealing needs.

This relentless focus on excellence ensures that every process and product we deliver meets the highest standards of efficiency and accuracy, solidifying our reputation as a global leader in operational excellence. With Datwyler, you can be confident that you’re partnering with a team committed to delivering excellence in every detail, with the ability to harness capabilities from across our sites.

GLOBAL PRESENCE, LOCAL EXPERTISE

Datwyler’s Worldwide

Sealing Sites Supporting the US

Datwyler’s expansive global network ensures we bring you local expertise backed by world-class capabilities. Our facilities around the world specialize in various product ranges, each contributing to the comprehensive, one-stop portfolio of solutions we offer.

- Ontario, CA Facility (Parco Products)

Our Ontario location is the 154,000 square-feet hub for the innovative Parco product line, delivering advanced sealing solutions tailored to a variety of industry needs. Ontario is ISO 9001, ISO/TS 16949, AS9100, AC7115, and ISO19025 certified, reflecting our adherence to the highest quality norms, including deep expertise in providing aerospace solutions. The range of equipment in Ontario also reflects our ability to provide you with practically any standard and custom O-Ring solution, including a wide range of compression and injection molding systems, extensive downstream processing equipment including cryogenic tumblers, vibratory separators, cryogenic deflashers, postcure ovens, and the latest in vision inspection Vario equipment. This enables us to produce at a high piece/hr rate so that we can handle even your biggest needs, quickly – and with the highest Swiss-driven quality standards. - Vandalia, OH Facility (Parco Products)

Specializing in Parco O-Ring products, the Vandalia facility is a key player in producing high-quality O-Rings, known for their durability and precision. - Dallas, TX Facility (Double E Range)

The Dallas facility is home to the Double E range, offering a diverse array of custom molded rubber products, designed to perform in the most demanding environments, as well as an extensive range of production equipment and machined metal solutions for the energy sector.

- Montgomery, TX Facility (TST Range)

Our Montgomery location focuses on the TST range, providing exceptional machined metal parts, renowned for their quality and reliability in the energy sector, as well as extensive machined thermoplastics capabilities. - Gray, LA Facility (Olympian Range)

The Gray facility is dedicated to the Olympian range, showcasing our prowess in custom machined metal parts, suited for a variety of industrial applications. - Nový Bydžov Czech Facility (Mixing Facility)

This facility stands as a testament to our commitment to material innovation. The Nový Bydžov location is pivotal in developing and mixing a wide array of compounds, offering a foundation for the creation of high-performance products across our ranges as well as providing specific compounds to any industry producing elastomer products. - Schattdorf Swiss Facility (Tooling)

This facility offers extensive tooling expertise across any industry, with the equipment and staff to match – teams with specialized education in automated CNC turning, milling, and eroding machines, and 90 serial tools, 60 prototype tools, and the ability to manage up to 700 repairs, including spare part production.

Each of these facilities plays a crucial role in delivering the consistent quality and excellence that Datwyler is known for, ensuring that no matter where you are, you have access to our best-in-class solutions and expertise. And any of the facilities can pull expertise and capabilities from across the sites, making us an efficient one-stop shop for whatever your need.

QUALITY

State-of-the-Art Production and Digitalization

We offer our customers a globally advanced production platform, integrating quality certification and high-level digitalization, to produce high volumes with consistent quality.

DPS MODEL

The Datwyler Production System (DPS) Model

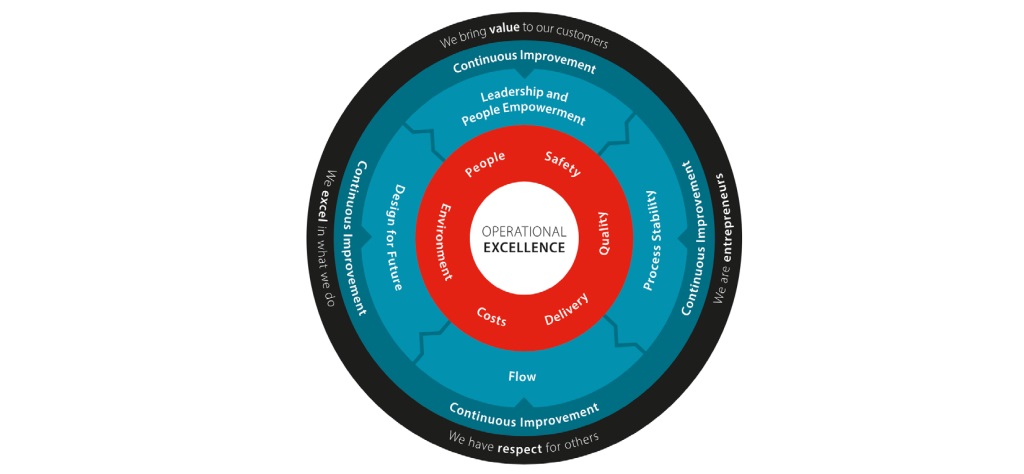

Built on Datwyler’s core values and lean principles, the DPS Model encompasses six key dimensions – Safety, Quality, Delivery, Costs, Environment, and People – aiming to achieve and maintain operational excellence and a lean culture. This system not only enhances our global position but also reinforces our competitive edge.

YOUR EXPERIENCE

Enhancing Your Experience with the

Datwyler Production System

At Datwyler, our production system is built on five key pillars, each designed to directly benefit you:

- Leadership and People Empowerment: Empowering Your Success

We focus on continual learning and clear communication, ensuring thatour team is aligned with our long-term goals. This results in a committed workforce, ready to meet your needs with excellence and innovation. By maintaining transparency and leading by example, we ensure a partnership you can trust and rely on. - Process Stability: Guaranteeing Your Product Quality

By standardizing tasks and maintaining safe, efficient workplaces, we ensure the consistent delivery of high-quality products. This means you can count on us for reliability and excellence in every product we deliver, ensuring your operations run smoothly. - Flow: Streamlining for Your Efficiency

Our streamlined processes across business and manufacturing mean simpler operations, synchronized production, and a continuous flow of products. This translates to reduced production times for your orders, helping you get what you need faster and more efficiently

- Design for Future: Preparing for Your Tomorrow

Our investment in efficient factory designs and future-proof technology ensures that we stay ahead of the curve. This focus on innovation means we are well-equipped to handle your evolving needs, giving you a competitive advantage in your market. - Continuous Improvement: Evolving for Your Advancement

Our commitment to continuous improvement in our products, services, and processes is fundamental to our success. This culture of perpetual positive change means we are always finding new ways to enhance our offerings, ensuring that you benefit from the latest advancements and best practices.