Enhance Your Sealing Capabilities with Double E’s Advanced Rams

Engineered for Maximum Pressure Resistance

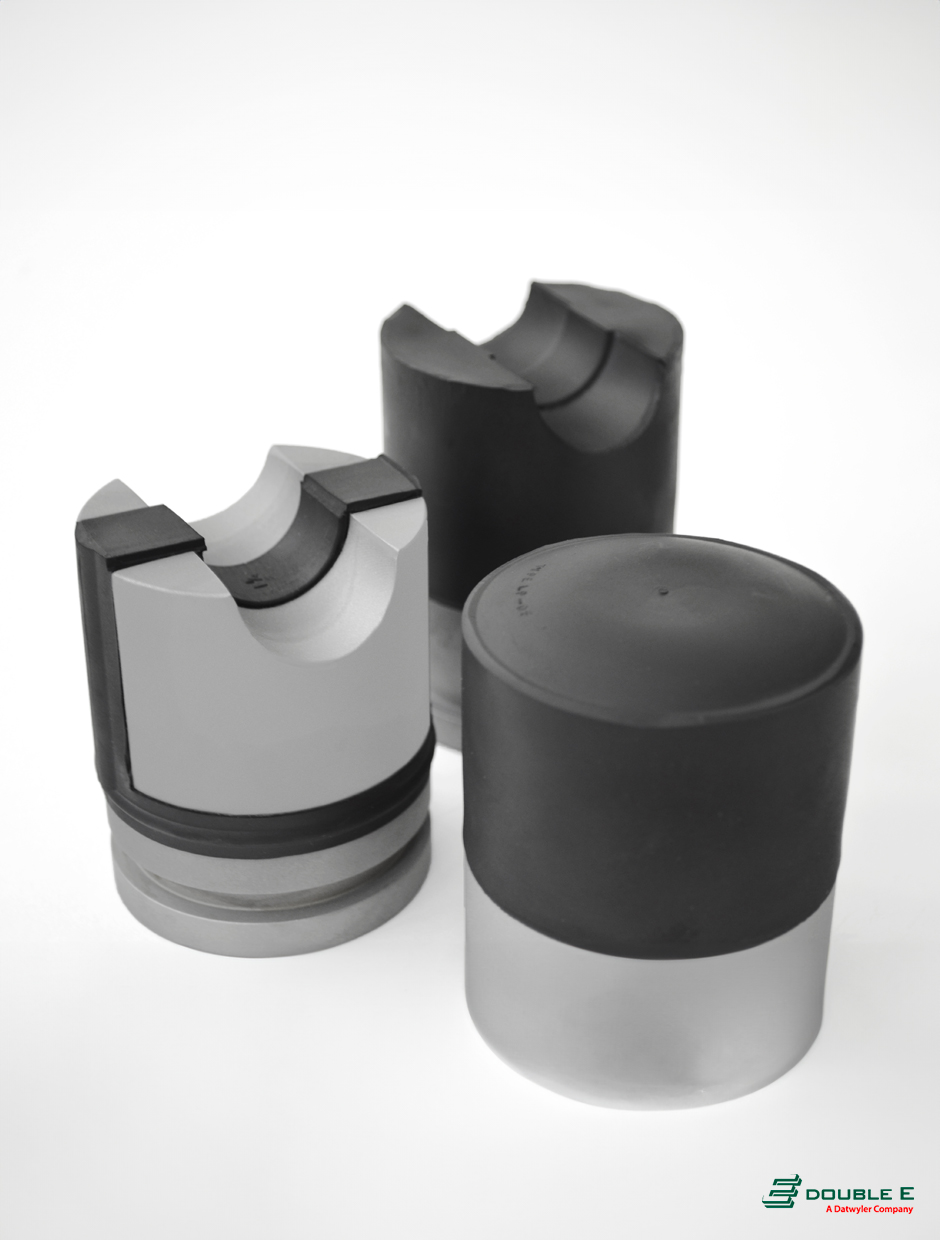

BOP Rams

At Datwyler, we understand that effective pressure control is crucial in your operations. That’s why we’ve developed a range of unique Ram designs, each offering exceptional pressure resistance for both standard and H2S service applications.

LD-DF: Steel-Reinforced Dome Faced Ram

The LD-DF Ram, with its steel-reinforced, dome-faced rubber design, is adept at closing and sealing on wireline/ tubing up to 9/16″. Versatile in functionality, it also provides an effective seal in the absence of a rod or wire in the hole. Rated for pressures up to 1,500 psi, the LD-DF Ram is a robust choice for diverse sealing requirements.

LP: Custom-Molded for Precision Sealing

Our LP Ram is specifically crafted to offer a precise seal on your small braided line sizes starting at 9/16″ rod or pipe. Molded to include a gap that matches the exact size of your rod or pipe, the LP Ram ensures a snug, leak-proof fit, rated up to 1,500 psi.

LP15: Unique Design for Versatile Closure

The LP15 Ram stands out with its ability to close on all rod sizes up to 1-1/2 inches. Its design is focused on preventing separation failures common in bonded assemblies, making it a reliable choice for pressures up to 3,000 in psi (in some sizes). The variable rams are ideal on rod lift jobs as they can seal on the polished rod, or different sized sucker rods as they are pulled through to surface.

HP6-FF: High-Pressure Steel Ram

Designed for the most demanding high-pressure scenarios, particularly when no rod is used, the HP6-FF Ram features a steel body with a rubber seal across its flat surface. Secure and reliable, it is rated for pressures up to 3,000 psi on lines and tubing up to 9/16″ diameter.

HP6: Customized for Your Rod or Pipe

Similar to the LP Ram, the HP6 Ram is manufactured to seal effectively on the outside diameter of your rod or pipe. This custom-fit Ram is ideal for operations requiring up to 3,000 psi pressure resistance.

HP10: The High-Pressure Specialist

Specially designed for use with the HP10 BOP, the HP10 ram is your solution for the most extreme pressure situations, handling up to 5,000 psi working pressure (10,000 psi for HP15 styles). Available for standard, H2S, or sour service, this ram is tailored for high-performance and reliability. HP10 ram can also be made with shear plates to cut your line or tubing when needed.

Explore our range of Rams to find the perfect match for your operational needs, where quality and durability meet innovation.