Material expertise is one of our core competencies at Datwyler. And a key part of that expertise is focused on developing sustainable, reliable materials.

Over the next few weeks, I’ll be sharing insights in the Datwyler TechTrend Pulse into how we’re dealing with that challenge, how our solutions can benefit both you and your stakeholders – and how you can partner with us to co-create the best custom response that’s specific to your needs.

Today I wanted to share an introduction into one of our focus innovation areas for sustainable material development — microfibrillated cellulose, or MFCs.

MFC – A Promising, Sustainable Substitute for Petroleum-based Materials

The substitution of petrochemical-based materials with renewable ones is an important step towards increasing sustainability. Cellulosic materials are promising candidates for this scope. These materials are renewable, abundant, and show a low environmental impact.

And that’s where microfibrillated cellulose (MFC) comes in.

MFC – How You, and Your Stakeholders, Can Benefit

There’s a lot to talk about when it comes to MFC and how it might benefit you.

First, its excellent properties. With its high stiffness, fibrils morphology, low density and mechanical properties, we think this is a promising alternative to traditional, petroleum-based solutions. And for you, that means a solution that’s up to the task of performing in high-pressure applications.

Second, it’s an excellent hedge against traditional material solution shortages, such as Aramid fibers. That means a better controlled material supply to ensure you and your customers avoid any down-time or delays.

Third, its sustainability. Unlike traditional solutions such as Aramid, which are petroleum-based, cellulose comes from a renewable source. That makes it a responsible solution to help reduce your own environmental footprint.

MFC – Adding a Uniquely Swiss Datwyler Touch

With rising awareness of PFAS, and the need for more environmentally friendly materials (we’ll share more insights about PFAS in a forthcoming TechTrend Pulse article), there’s a lot of discussion right now about sustainable material solutions.

At Datwyler, we closely listened to our customers’ needs and understood that a key concern about sustainable materials was whether they could show strong resistance in tough, system-critical environments. To address that, we decided to collaborate with EMPA, the Swiss Federal Laboratories for Materials Science and Technology. (The EMPA is a Research Institute of the ETH Domain – one of the world’s top technical and research institutes.)

The outcome?

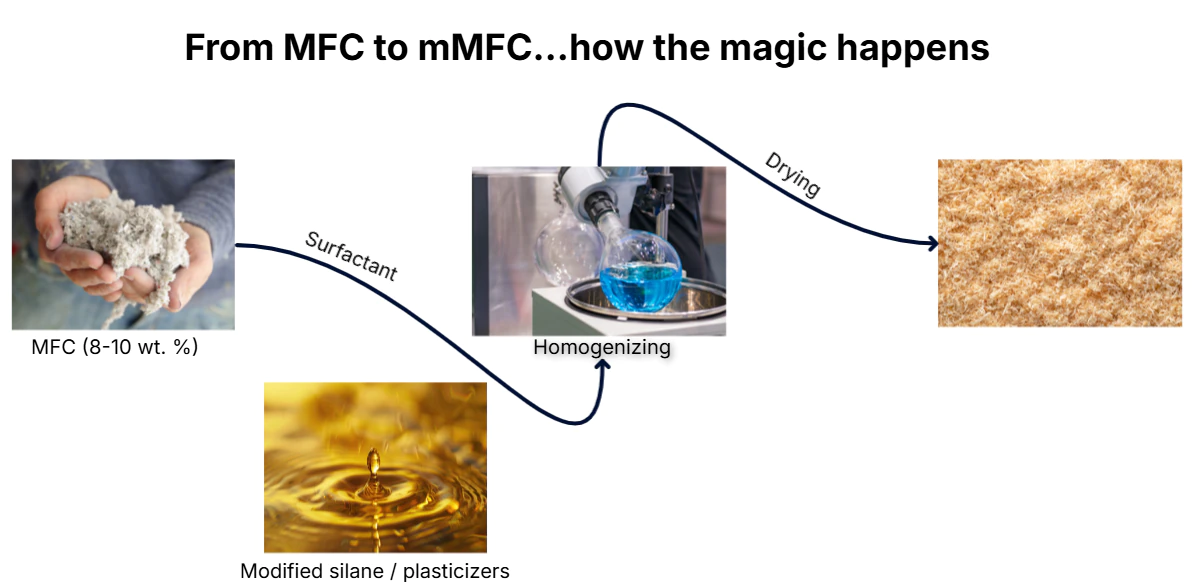

From MFC to mMFC – a Superior Solution from Datwyler

As a result of our work, we succeeded in modifying the surface of MFC, making it more hydrophobic. This more hydrophobic material, called mMFC, or modified MFC, smoothly disperses into a more hydrophobic polymer matrix – just like EPDM. And with its good compatibility between filler and matrix, our mMFC shows a strong reinforcing effect, even superior to those reached with conventional petroleum-based fibres.

mMFC – Potential Applications

We see mMFC as particularly suitable for sectors such as HVAC and Sanitary – for example, in making diaphragms for valves. But the potential applications are much broader, including other various industrial and mobility applications and in general any dynamic or high-pressure applications where an elastomeric seal normally reinforced with aramid fibers, textile or similar reinforcing technology is used.

mMFC – Come and Co-Create with Us

We’re pretty excited about mMFC – and think you might benefit from it too.

We’ll as mentioned share more information in TechTrendPulse over the weeks to come, but in the meantime, why not reach out to us at Contact Us – Datwyler Sealing to discuss mMFC further?

As we look to upscale production, my team and me would be happy to speak and see where we might have an opportunity to co-create a great solution together.

Best regards,

Bram Jongen

VP Materials and Surface Technologies

Datwyler Sealing