Datwyler has expanded its capabilities to support customers transitioning to hydrogen fuel cell technology. Working in partnership with leading global fuel cell producers, the company has further strengthened its portfolio of high performance and system-critical sealing materials and associated production techniques to provide solutions that cover the entire value chain – from hydrogen production via electrolyzer technology to actual use in the vehicle – specifically fuel cell.

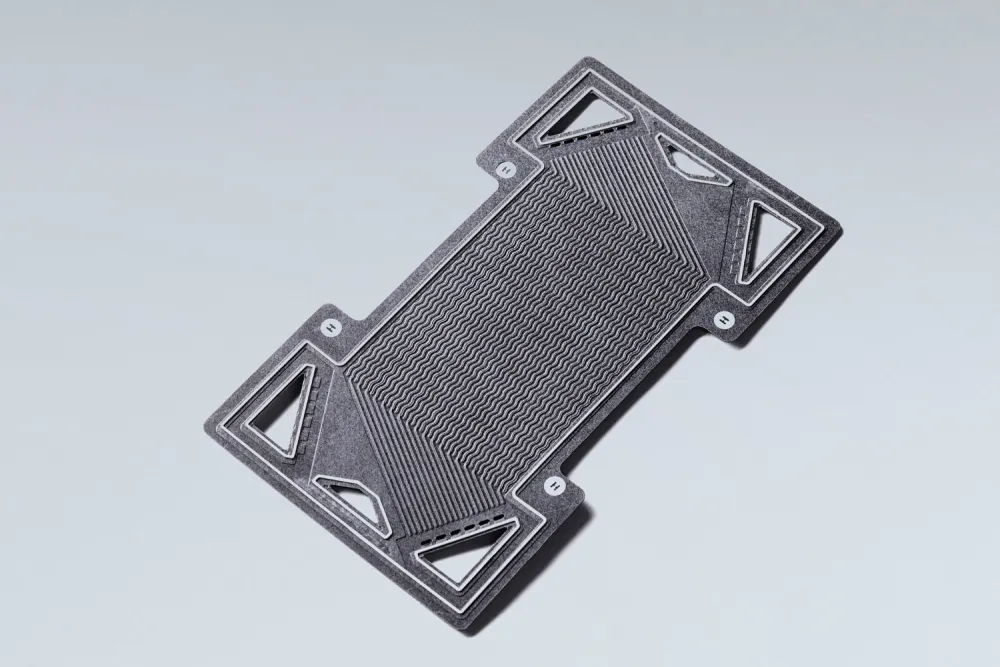

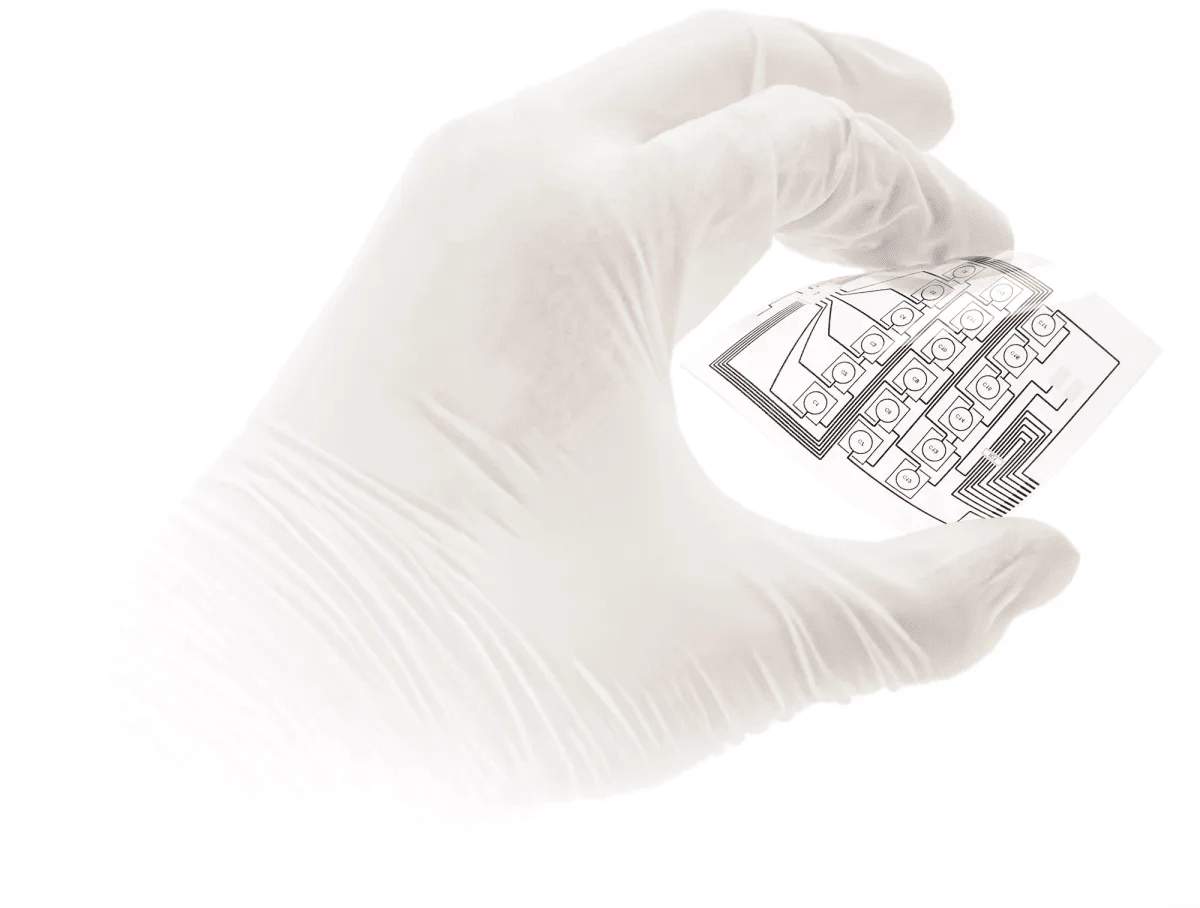

Datwyler’s focus on seals for bipolar plates (BPP) are critical, as they are the components within a fuel cell used to produce electricity through harvesting energy previously stored in hydrogen (and oxygen) molecules. The BPPs are produced using three main base material options – metal, graphite and composites. As a result of in-depth testing and analysis in conjunction with our elastomer technologies, we have determined that composite materials will, in mobility applications, achieve the best possible results when weighing challenges against performance. Composite BPPs are light, cost effective, easy to process and provide superior chemical resistance when compared with metal and graphite alternatives.

Within the fuel cell itself, the BPP must be sealed effectively, and the material must be capable of withstanding a variety of conditions, including prolonged contact with three separate media – hydrogen, humidified air and cooling liquid. Datwyler’s Technology & Innovation Labs, combined with specialist laboratories across Europe, are testing the effectiveness of materials, focusing on elements such as ion contamination, amongst others, to ensure the highest levels of performance.

Elastomers, in general, have been conclusively proven to deliver against a broad range of critical parameters. From their high absorption of mechanical energy to their excellent chemical resistance, they have enormous potential for fuel cell technology applications in combination with composite BPP.

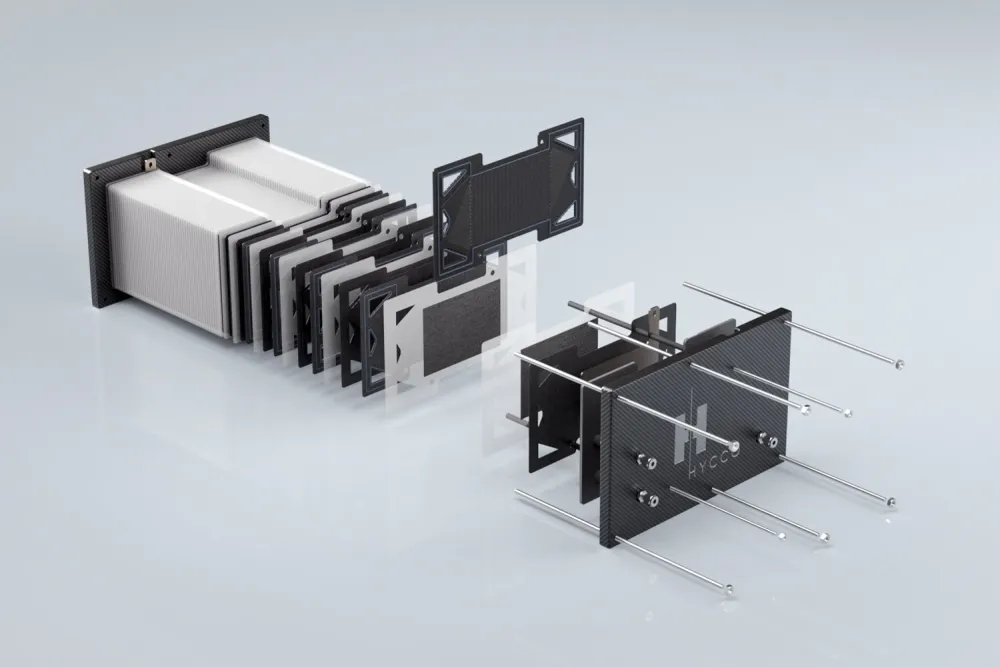

“Datwyler partners with HYCCO, a leading producer of BPP, to co-engineer a sealing solution that is highly effective and also scalable as demand increases. We are now in the process of developing the material options which will progress to processing trials. The results we have achieved so far prove that a co-engineering approach to emerging technologies is the best way of working. At Datwyler we have the capabilities in material expertise, operational excellence and solution design to ensure fuel cell producers that we can deliver reliability and quality, supported by a global network.”

Dr. Sarah-Elisabeth Dechent

Material Development Manager

“HYCCO is very pleased about the new strategic partnership with Datwyler. Together we want to develop a cost-effective solution for the production of gaskets for proton exchange membrane BPP. Datwyler has a tremendous experience in elastomer formulation, and mass production of complex sealing parts. Datwyler has invested into best-in-class R&D means to meet the various challenges ahead. We are therefore very pleased and confident that this strong partnership will enable HYCCO to provide a turnkey solution of sealed and assembled composite bipolar plate, for hydrogen fuel cells destined for heavy mobility markets.”

Romain Di Costanzo, Chief Executive Officer at HYCCO